surface grinding machine pdf

The common grinding machine operation are surface cylindrical internal and centreless grinding. Table 41 A typical ceramographic grinding and polishing procedure for an automatic polishing machine Platen Head Step Abrasive and lubricant Time min frequency rpm frequency rpm 1.

Chapter 5 Surface Grinder Manufacturing Processes 4 5

1 plain cylindrical 2 internal cylindrical 3 centreless 4 surface 5 off-hand 6 special and 7 abrasive-belt.

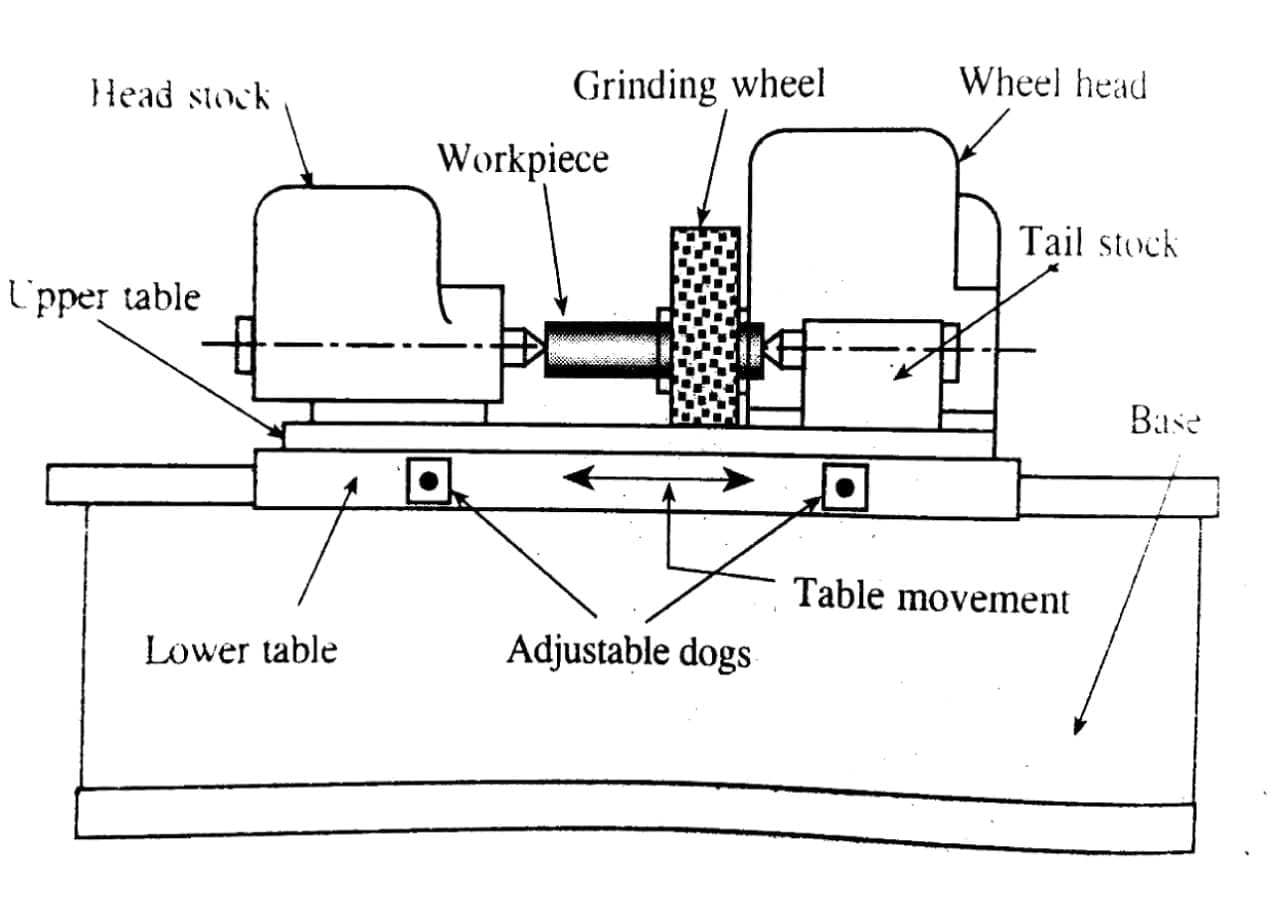

. Workpieces are fastened to the workpiece and wheel. It is the most versatile and widely used machine in industries institutions etc. RECIPROCATING SURFACE GRINDING MACHINE for fastening the workpiece to the table.

From surface grinding multi-axis CNC machining turning welding assembly coating laser engraving and packaging we operate as a true one-stop job shop. Vishwakarma Submitted as a partial fulfillment of Bachelor of Engineering BE. UNITED GRINDING is your solutions partner with products and services designed to assist you throughout the life cycle of your CNC grinding machine.

We know your profitability relates directly to the toolholders cutting tools and accessories you utilize. Complete your machine with unique high precision machine tool accessories from Productivity Inc. Semester VIII MECHANICAL 2013 - 2014 from Rizvi College of Engineering New Rizvi Educational.

Non-magnetic are held by vices or. Grinding is quick and relatively easy process but can. D the same surfaces prepared to two grades of surface quality St 2 and St 3 by manual scraping and wire-brushing - machine brushing - grinding -etc.

From concept to finished product WS Machine Tool is a vertically integrated manufacturer providing machine shop support for businesses of all sizes. A Project Report On DESIGN AND FABRICATION OF SHEET METAL ROLLING MACHINE Submitted By HARSHDEEP SINGH INAYATULLAH FAROOQUI Under the guidance of Prof. I assumed that you already have a brief idea about Grinding Machine.

The bed is made from Cast iron or nickel cast iron alloy and is supported on broad box-section columns. Here the workpiece is fitted with a magnetic chuck attached to a work table of the grinder. Grinding lathe tool bits is a bit of an art.

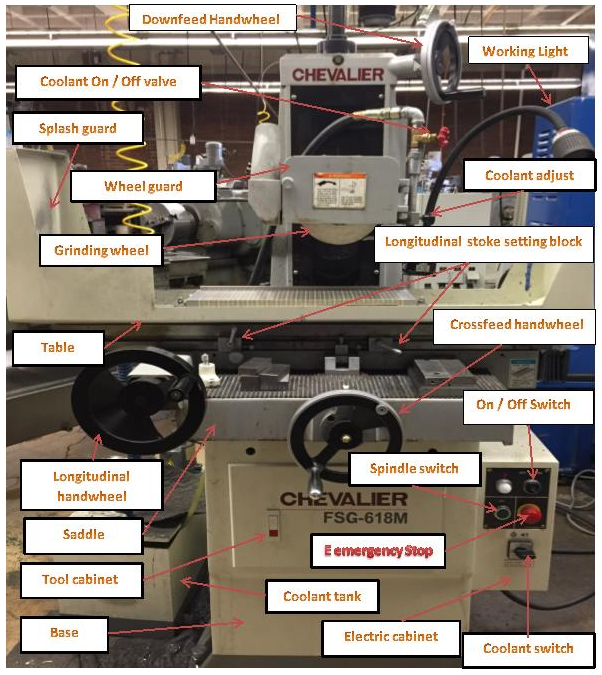

Plane grinding 240-grit bonded diamond disc sprayed 051 or until specimen is flat 200300 120150 opposite. G5963 6 x 12 Surface Grinder w Stand Precision grinding perfect for the small tool room and metalworking enthusiast. A grinding machine is a production machine tool used in the manufacturing industry in which the grinding wheel is attached in the tool post and the workpiece is fixed to the work table and when the operation starts it removes the unwanted material to get the desired surface finish correct size and accurate shape of the workpiece.

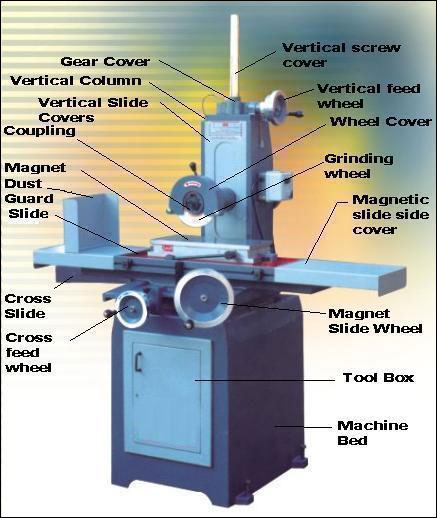

Aluminium The surface shall be hand or machine abraded with non-metallic abrasives or bonded fibre machine or hand abrasive pads to impart a scratch pattern to the surface. The common types of grinding machines include the following. The planer is a machine tool designed to produce plane and flat surface on a workpiece which is too large or too heavy.

A study published online in Optics Express has proposed the use of surface-enhanced Raman scattering spectroscopy SERS for this purpose. The same surfaces prepared to four grades of surface quality Sa 1 Sa 2 Sa 2½ and Sa 3 by blasting with various abrasives. Simultaneous and ultra-sensitive SERS detection of SLPI and IL-18 for the assessment of donor kidney quality using black phosphorusgold nanohybrids.

Modern grinding machines grind hard or soft parts to tolerances of plus or minus 00001 inch 00025 millimetre. The grinding wheel or plate typically rotates at a high speed around 200-1000rpm and a coarse bonded abrasive 40 µm is used. Grinding Tool Bits When you purchase a new lathe tool bit it might have an angle on the end but it is not properly sharpened for turning.

It takes some practice to get good at it. Now let us discuss each one by one 1. Grinding operations are utilized by a table that moves on a horizontal plane and a grinding wheel that moves along a vertical axis.

The accuracy surface finish and time required to complete a job is extremely predictable making it much easier to quote EDM leaves a totally random pattern on the surface as compared to tooling marks left by milling cutters and grinding wheels. If you not learned yet. Grinding is the operation of removing the metal in the form of minute chips by feeding the work against a rotating abrasive wheel known as the grinding wheel.

The bed of the lathe machine is the base on which all the other parts of the lathe are mounted. A grinding machine often shortened to grinder is one of power tools or machine tools used for grindingIt is a type of machining using an abrasive wheel as the cutting toolEach grain of abrasive on the wheels surface cuts a small chip from the workpiece via shear deformation. The G5963 6 x 12 Surface Grinder allows you to resurface metallic workpieces to create high-tolerance flat surfaces.

Lathe Machine is a machine tool that uses a cutting tool for removing the material from the surface of the workpiece which is held in the chuck for holding the workpiece and feed was provided by the tool on to the workpiece for the removal of material. It is also called an abrasive machining process where abrasives are placed on the surface and corners of the grinding wheel so as to do the finishing process with much more accuracy. Grinding Machine Operation.

The workpiece is securely fixed on. Surface Grinding Machine is a machine in which a grinding wheel is used as a cutting tool for removing the material from the surface of the workpiece. Grinding is used to finish workpieces that must show high surface quality eg low surface.

It involves grinding flat surfaces. You need to create a cutting edge that is sharp extends out so that the cutting edge and not. Concave surface on hard brittle materials such as single crystal sapphire can not be finished via form grinding due to process-induced cracks Diamond turning center can be used for non ferrous materials but it is a super-precision machine-tool The equipment cost is 20 crores besides the expensive operational cost 1.

The EDM process leaves no residual burrs on the workpiece which reduces or eliminates the need for. Abrasive blast cleaning to achieve a surface profile using non-metallic abrasive media which is suitable to achieve a sharp and angular surface profile. Both internal and external surface of a workpiece may be ground by using a.

A surface grinder is a machine tool used to provide precision ground surfaces either to a critical size or for the surface finish. Grinding can be defined as the rapid removal of material from a sample either to reduce it to a suitable size or to remove large irregularities from the surface. The typical precision of a surface grinder depends on the type and usage however 0002 mm 00001 in should be achievable on most surface grinders.

This grinding machine has an internal pump and piping network for The reciprocating surface grinding machine is a horizontal-automatic application and recirculation of a coolant to the type surface grinding machine. Its upper surface is either scraped or grounded and. As my previous article of Grinding Machine I told grinding is an important operation in manufacturing industry to get a final product so for that we need to know about the grinding wheel and its properties so that we easily choose a right wheel for the right material.

14 Types Of Grinding Machines Working Diagram Pdf

Guru Arjan Machine Tools Surface Grinder Machine Surface Grinding Machine Surface Grinding Machine Manufacturer

Hydraulic Circuit For Surface Grinding Machine Explained In Details Engineering Arena

Grinding Machine Definition Parts Working Principle Operation Advantages Application Notes Pdf

Surface Grinding Machine Definition Parts Working Advantages Disadvantages Applications Pdf

Une Maison Confortable Pour Vous Parts Of Surface Grinding Machine Pdf

Manual Surface Grinder Wheel Head Moving Surface Grinders Manufacturer From Faridabad

8 Types Of Grinding Machine Parts Working Principle Grinding Wheel Complete Details Engineering Learn

14 Types Of Grinding Machines Working Diagram Pdf

Muhammad Musa Muslimmuhammad313 Profile Pinterest

Horizontal Spindle Surface Grinding Machine With Reciprocating Table Download Scientific Diagram

Everything You Need To Know About A Grinding Machine Studentlesson

Horizontal Spindle Grinding Operations A Traverse Grinding And B Download Scientific Diagram